Company

ZARRI S.r.l. is based in Castello D’Argile, 20 km north of Bologna.

Founded by Angelo and Franca Zarri in 1973, it has always stood out for the maximum quality and speed of its production, the just in time service for standard catalogue products, and the logistics offer made available to its customers..

Zarri boasts a wide range of products to satisfy all procurement needs for special and standard metal parts.

The main product lines are:

- Special fixings from design

- Standard fixings

- Wire or metal rod articles

- Sheet metal structures – cutting, bending, stamping, and drawing processes

- Tube structures – bending, cutting, calendering, shaping, welding, molding processes

- Complex structures and designs made of metal rods, sheet metal, tubes, fixings, turned parts and plastic elements assembled, welded or fitted together

- Tension, compression and torsion springs, turned and milled items

- Standard or custom-made items for the ceramics industry: manual tile laying tools, tile lifters, adjustment keys, sheet metal supports for perimeter elements, anti-fragmentation panels, windproof systems, retail shelves.

It employs 40 people on an area of 21,800 m2, of which 5,500 are covered, and supplies more than 4,000 customers (25% export).

TECHNOLOGY

ZARRI annually processes 2,000 tons of steel in more than 6,400 production batches. Founded in 1973 for the production of U-bolts, it later evolved into the production of many other types of fasteners, both custom-designed and standard. Today, more than 50 years after its foundation, it offers a wide range of items ranging from wire products, sheet metal products, springs, tubes, turned parts, and both special and standard products for the ceramic world. The latter allowed Zarri to register the first company patent, a tile laying machine for laying ceramic tiles and slabs. Zarri is also able to create complex structures involving the aforementioned parts, assembled together, welded and/or mounted. The company’s production lines are diversified to quickly meet requests for small, medium and large batches. The main processes are: bending, threading by rolling/deformation, shearing and chamfering, threading by removal, cutting, welding, drilling, Milling, extrusion, coining, engraving marking, laser marking, hot and cold stamping, boring, hot bending, rolling, calendering, turning, broaching. By relying on qualified external companies, we are able to carry out various heat treatments (stress relief, tempering, induction hardening, etc.) and anti-corrosion coatings (electrolytic galvanizing, hot-dip galvanizing, zinc/aluminum, Dacromet® and Geomet®, chrome plating, burnishing, cataphoresis, painting, phosphating, and many others upon customer request).

LOGISTICS

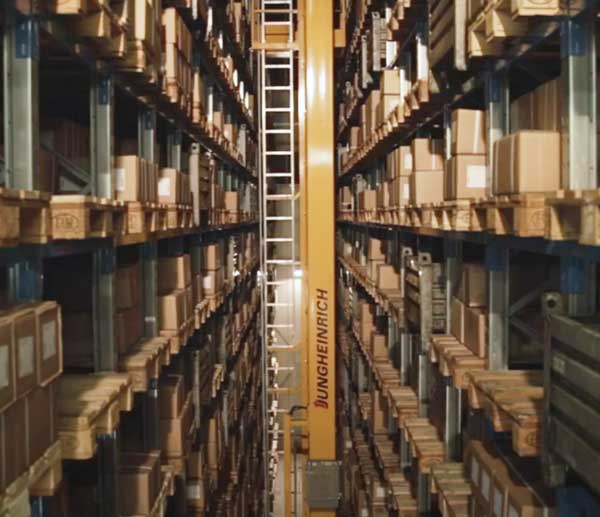

Despite being born as a manufacturing company, Zarri stands out for its strong focus on service and logistics.

The company is equipped with three latest-generation automated warehouses.

The largest, recently doubled in size, has a capacity of 1,400 pallet spaces and is 60 meters long and 14 meters high.

The purpose of such an important logistics organization is multiple.:

- guarantee just in time delivery of standard products to its customers

- Offer call-off stock according to framework contract logistics for special items on customer request

- Complete the supply of fastening items with complementary products ready for delivery such as nuts, washers and screws

In order to better organize in-house flows, the company has installed two more automatic drawer warehouses:

- The first, equipped with 78 drawers for a total height of 14 meters, allows for easy storage and retrieval of consumables, paper archives, documentation, and everyday items. It is shared with the warehouse, which also stores accessories for sold items and some of the packaging and PPE..

- The second, equipped with 50 drawers for a total height of 12 meters, inside the workshop, for production use, to store all types of molds and rollers, to have maximum order and precision of use..

QUALITY

Zarri has a certified Quality Management System.

Since 2009, the company has been ISO 9001:2015 certified by Kiwa Cermet Italia S.p.A. of Bologna.

The extreme attention to the supply of quality products has led Zarri to achieve a trend maintained over the years of 99% compliant batches per year. The goal is maximum quality, a distinctive feature appreciated by all customers who choose it as a partner.

The system through which Zarri manages the quality of its products requires that each component is subjected to numerous checks throughout the production process.

The organization uses diversified control and inspection technologies, depending on the type of measurement required.

From constant measurement during production, to the use of digital measurement machinery, such as Keyence products for immediate measurement detection, up to latest-generation technologies capable of extracting measurements in three dimensions with infinitesimal precision within a virtual mask that contains, together with the measurements, all its tolerances.

WE USE GREEN ENERGY

Photovoltaic panels totaling 190 kWp have been installed on the roof of the production facility. These provide more than 50% of the company’s electricity.

WOMEN’S ENTERPRISE

A metalworking industry outside the box: Zarri is a female-run business.

The metalworking industry has always been perceived as a male-dominated sector.

Zarri turns this narrative on its head: 76% of our share capital is held by women, and our legal representative is also a woman.

But it’s not just about quotas: Zarri boasts 16 out of 40 female workers, 8 of whom are in production and the warehouse, which is headed by a woman. Our sales office is all female, boasting 7 women in sales.

We believe in the value of shared work between men and women.

In a sector where the presence of women is still an exception, we experience it as… Read more here

Our story

Prologue

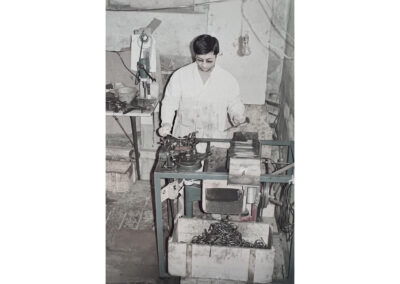

Giorgio Zarri, a native of San Giorgio di Piano (Bologna), the son of farmers, had developed a strong interest, passion and experience in mechanics, and in particular in agricultural mechanics, from a young age.

In 1966, after a difficult experience at the Italsider plant in Taranto (now ILVA), he moved with his wife Alba Gurini and their three children Franco, Angelo and Franca to Cento di Ferrara.

On the construction sites where he had carried out his work, he had had the opportunity to see how many of the fastenings used in them were imported from abroad and therefore decided to seize the opportunity and create a machine suitable for the mass production of U-bolts, much in demand by plant installers.

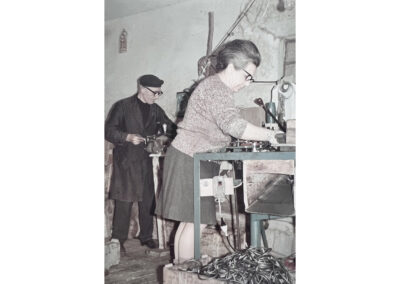

In a short time, Giorgio moved from the construction of the first manual prototypes to the creation of a machine for U-bending threaded rods, in various diameters and shapes, based on orders that soon began to arrive. arrive, while the whole family is involved in the enterprise on a daily basis.

Birth and development of the company

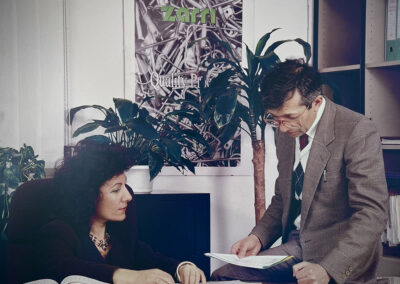

The business grew successfully: Angelo, still a mechanical engineering student, was the technical mind behind the company and, together with his sister Franca, a skilled sales manager, founded the company “Zarri Sdf di Zarri Angelo e Franca” in 1973.

His parents, Giorgio as a toolmaker and Alba in production, were the operational arm of the family artisan business.

The high quality of their products and the careful management of their customer relationships fueled orders, which led to the first hiring of staff and the search for large, suitable spaces.

In 1977, the company purchased land in the new industrial area of Castello d’Argile (BO). The new industrial warehouse, a futuristic tensile structure designed by his brother Franco, a civil engineer, was built there, the original nucleus from which subsequent expansions were developed.

Over the years, the organization grew and strengthened, from the initial phase pioneering in the 1970s, to greater structure in the 1980s with the

regularization into a general partnership and the first expansions.

During the 1990s, the company achieved ISO:9001 certification, transitioned to an LLC, and significantly expanded its presence in foreign markets.

The beginning of the new millennium marked another major step for the company, with the construction of the first automated warehouse for the

storage of finished products, combined with a significant expansion of the covered area.

In 2002, Engineer Angelo Zarri passed away in a tragic accident; His entrepreneurial foresight and the forward-looking vision that has always characterized the company’s decisions have laid a solid foundation for the growth of the organization, which, over the years, has established itself as a leading manufacturer of steel fasteners in the European market.

From the 2000s to the present, the company has experienced constant economic growth.

The acquisition of increasingly cutting-edge technologies, including numerous CNC machines, the digitalization of processes, the use of renewable energy to power production, the development of highly qualified protocols, and a work ethic focused on fairness, dignity, gender equality, sustainability, and ecology.

All this makes Zarri a company capable of meeting the challenges of the new millennium.

Zarri today

In 2024, major expansion work was completed, bringing the plant to a total of 5,500 square meters, with a vast fleet of machinery for the production of parts based on customer designs and the Zarri catalog.

Thanks to the wide range of machinery and a flexible operating method, the organization is able to satisfy a wide range of customers operating in a wide variety of sectors.

Opening up to new product sectors is a primary goal for Zarri; the recent entry into the ceramics market led to the acquisition of the first company-owned patent.

The company’s vocation has always been Made in Italy production; A major competitive advantage lies in its certified quality – widely appreciated throughout Europe – and in its logistics which, thanks to a recent doubling of the automatic warehouse now capable of holding 1300 pallet spaces (a rare case for a manufacturing company), is able to guarantee a true just-in-time service to its customers.

The people

After the untimely and tragic passing of Engineer Angelo Zarri, the company was continued by Franca Zarri (CEO) and her husband Angelo Cocchi. They are now joined by Sara Zarri, Simone Zarri, and Chiara Cocchi, the third generation of a business that remains family-run.

The Zarri company looks to the future with confidence, aware of its strong roots: its foundations are rooted in the history, ingenuity, and commitment of those who have contributed to making it the dynamic and well-structured company it is today.

Customers say about us…

“Zarri stands out for his precision, punctuality and courtesy.”

C. of the C.M. company (Italy) – Zarri’s customer since 1979

“The Zarri company has been our trusted partner for many years and has always stood out for its quality, punctuality and competitive prices.”

C.B. of company B. (Italy) – Zarri customer since 1977

“We are very satisfied with the level of services provided by your company”

S.D. of the company D. (Belgium) – Zarri customer since 2008

“Don’t change anything, we are completely satisfied with Zarri and hope to work even harder next year.”

O.S. of company A. (France) – Zarri customer since 2012

“Thank you and everyone at Zarri for the wonderful collaboration since we started working together! It’s always a great experience contacting you; we’re not used to this type of relationship with other foreign suppliers. In addition to the fantastic quality and very competitive prices, we’re very satisfied with your high standards and reliability.”

F.T. of E.A. (Netherlands) – Zarri customer since 2011